Re-Aves was born in 2014 and is located in Helmond, Brainport region.

Re-Aves operates as a value-added supplier and as a partner when it comes to complex mechatronic systems, industrial modules and mechanical components.

Our “Manufacturing Services” offers support to Original Equipment Manufacturers (OEMs) in order to achieve their business objectives. Our aim is always to make our clients’ tasks easier so that they can focus on developing their core business. The Re-Aves services refer mainly to the following markets: High-tech, Biotech, Automotive and Renewable energy.

Re-Aves offers their customers build-to-print solutions under the term “Manufacturing Services”. These build-to-print solutions will support Original Equipment Manufacturers (OEMs) to realize complex mechatronic systems, modules and mechanical components. We work from prototype to series production. In this realization process, Re-Aves will constantly focus on your product optimization, quality and lead time. It is our objective to work as efficiently as possible. Close teamwork with our customers will lead to optimal results.

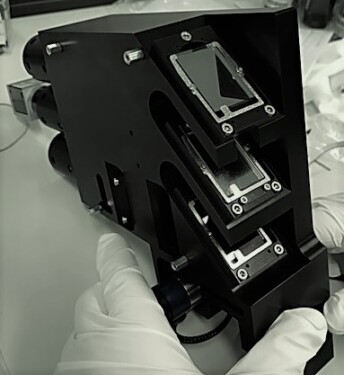

System Supplier

For the development of mechatronic systems, we always work on the basis of the TPD (Technical Product Documentation) made available by the relevant customer. We will ensure that all required parts and purchase parts are produced or purchased in accordance with the specifications provided. In the assembly process we work strictly according to the specifications of the mechatronic system to be produced. Before any mechatronic systems leave our production facilities, their function and quality are thoroughly tested, in consultation with the customer.

Industrial Modules

Complex mechatronic systems often consist of underlying (mechatronic) modules. For various reasons, clients may decide not to have a complete mechatronic system realized, but to outsource its implementation at module level. Our Re-Aves experts call these Industrial Modules. These build-to-print solutions are also based on the TPD (Technical Product Documentation) provided by the customer. On the basis of your TPD specifications we can produce and assemble your modules and, if required, perform full tests.

Spare Parts Management (SPM)

One of the facilities of the Re-Aves build-to-print portfolio is our service Spare Parts Management (SPM). In close consultation with our customer, we will discuss which parts are essential for their production process or mechatronic system. Efficient management of the correct spare parts will optimize your production process and minimize downtime. Re-Aves can take care of the production, inventory management and any logistical services so that you can focus on your core business.