What we do

We develop and deliver technology to ensure that our customers’ products and product-data are safe, authentic, transparent and processed in a flexible and sustainable manner.

How do we do it

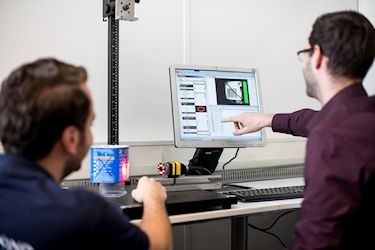

Our systems integrate optical technology to automate quality inspection real-rime and inline.

This requires skills such as machine vision, machine learning, mechatronics and robotics.

We enable increased output whilst increasing quality, efficiency and flexibility at reduced total cost of ownership.

Our purpose

We are all One-of-A-Kind-personalities and want to be truly ourselves, in an authentic manner.

To achieve that, we make everyone feel safe by providing an open working environment where people develop themselves, our technology and the business.

We translate “making errors” into “learning fast” and share knowledge as a form of continuous improvement.

Innovation and growth is in our DNA, together with sustainability and profitability. Our team has the freedom, space and responsibility to innovate for our customers and for themselves because that will make us grow.

Our leading principals

Create your own destiny: Dream and dream BIG, to leverage the power of self-fulfilling prophecies.

Do not wait for tomorrow if it can be done today: Freedom and Accountability are one. Make decisions and take actions needed.

Think out of the circle: Improve and innovate, as a person and for the business.

Walk the extra mile and do not give up.

Promote diversity and respect: Enable individuals to develop and flourish from their individual strengths and personalities.

About the companies

Beltech

Industrial machine vision and robotics, solutions to improve efficiency, effectivity and output of any process.

Our market is the European production industry, from food to farma and from automotive to electronics where we act as your System Integrator.

Vimec

The focus of the Vimec activities is in development, build and validation of inspection machines for farmaceutical glass products. In this niche market we provide a world-coverage.

Smart Vision Center

Being a Cognex Partner System Integrator, SVC’s activities are parallel to Beltech, yet dedicated to the solution-package of Cognex Smart camera’s.

Crux Agribotics B.V.

Start-up company founded in 2015, development of automated systems for the worldwide agro & food market.

Crux Agribotics applies our industrial IP in vision and robotics to increase efficiency and quality in handling – harvesting, sorting, packaging – of organic products such as vegetables.