Company

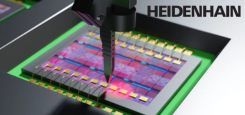

ASMPT ALSI is the inventor of multi-beam laser dicing and grooving. The multi laser beam dicing and grooving process is the technology with very low thermal impact while having a very high productivity. ASMPT ALSI’s solutions enable you to reduce your manufacturing cost significantly and to execute your semiconductor technology road map.

Technology

To enable the low cost of ownership all modules within the system support and contribute to achieve this proposition. To keep up with the demanding semiconductor market, continuous technology development enables; smaller, better and more cost effective products for wafer dicing and grooving applications.

Products

We offer laser dicing and grooving systems that enable the lowest cost of ownership through the shortest process time and high flexibility. This ensures that ASMPT ALSI’s laser systems are ideally suited for your application.

Application

We develop laser dicing and grooving solutions that enable semiconductor manufacturers to reduce the product manufacturing cost through yield improvement, higher productivity, and increased number of dies per wafer. Our expertise is in RFIC, LED, IC, Low-K and Discrete.