Additive Studios – Consultancy Services for MetalFab Customers

At Additive Industries we don’t just provide a machine – we support our customers throughout their entire journey with the MetalFab which is why we have created our Additive Studios AM consultancy business. Our specialist team of design,…

Sandvik and Additive Industries announce PLT powder supply partnership

Collaboration providing controlled and safe metal powder supply direct from a powder atomizer through the Additive Industries innovative PLT factory workflow solution. Read more

Powder Load Tool (PLT)

We recognise the critical nature of the metal powder in our systems from a quality and safety perspective,which is why the MetalFab is designed to minimise the exposure of powder particles to oxygen, moisture and human contact. The Powder Load Tool (PLT) can be filled with metal powder directly at the atomization source under inert conditions and…

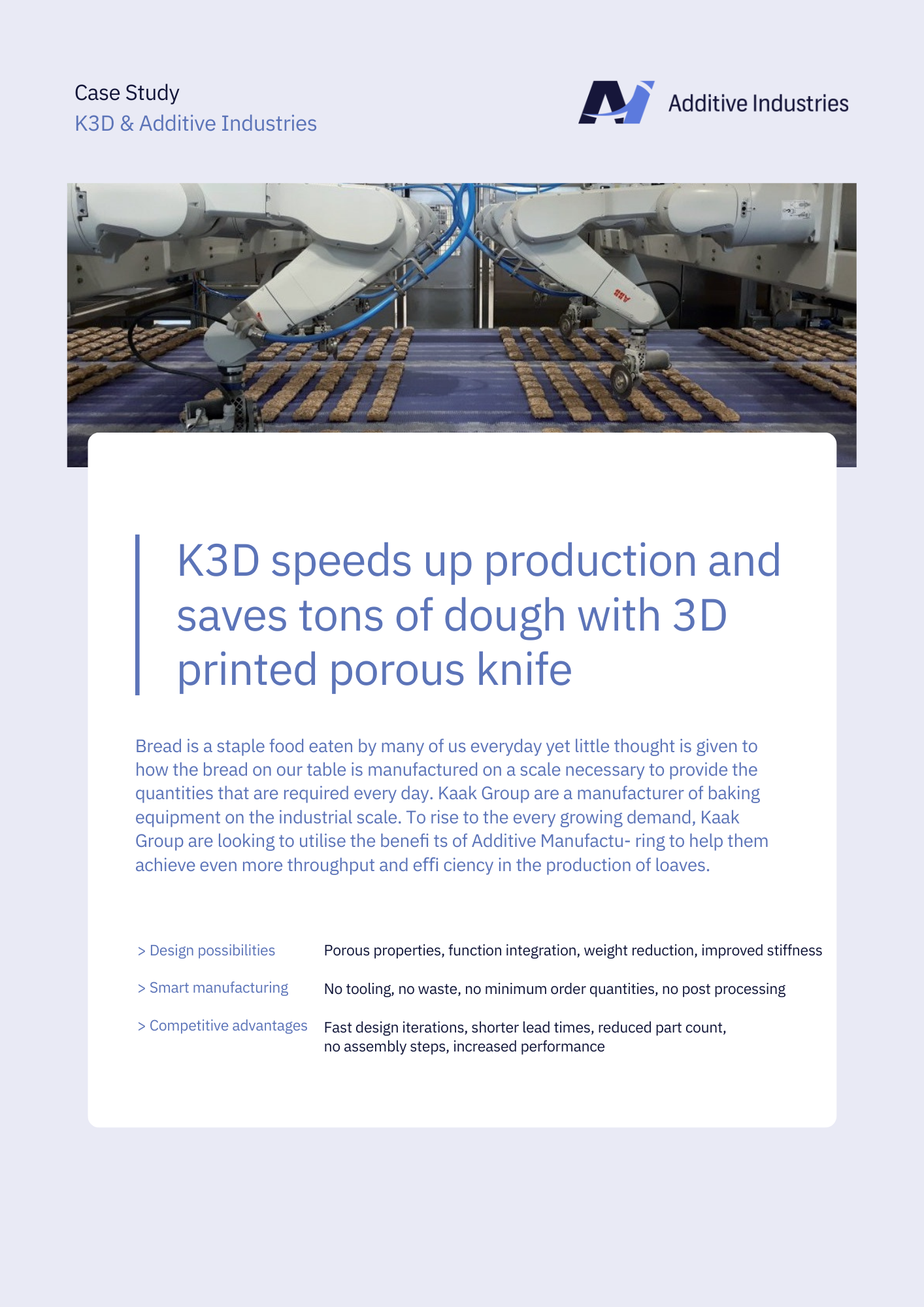

Case study: K3D speeds up production

Kaak Group is a leading manufacturer of industrial-scale baking equipment. As the demand for their products continues to grow, Kaak Group is eager to harness the advantages of Additive Manufacturing to further enhance productivity and efficiency in loaf production. Read more

Our MetalFAB Portfolio: Titanium Based Alloys

.png?width=2316&height=1852&name=Ontwerp%20zonder%20titel%20(44).png)

This well-known light alloy is characterised by having exellent mechanical properties and corrosion resistance combined with low specific weight and biocompatibility. This material is ideal for many high-performance engineering applications, for example in aerospace and motorsport, and also for the production of biomedical implants. Read more

Managing powder feedstock safely

Managing powder feedstock safely is vital for both quality and operator safety. The MetalFab system is designed to minimize exposure of powder particles to oxygen, moisture, and human contact throughout the process.With the Powder Load Tool (PLT), powder can be:* Transferred under inert conditions directly from the production source to the site* Maintained in inert conditions…

Dynamic Laser Assignment for MetalFab Systems

Discover the enhanced capabilities of Additive Industries’ MetalFab full-field multi-laser technology with the upgraded Dynamic Laser Assignment software tool. The second generation of this software provides MetalFab users with significant improvements in performance, quality, and visualization, optimizing the efficiency and precision of additive manufacturing processes. Download

Whitepaper: Production of High Quality GRCop-42 Copper Alloy Parts with MetalFab

Find out how Additive Industries ensures consistent, high-quality GRCop-42 parts in a highly controlled and enclosed environment using the MetalFab G2 system, based on NASA’s powder specifications. Read more

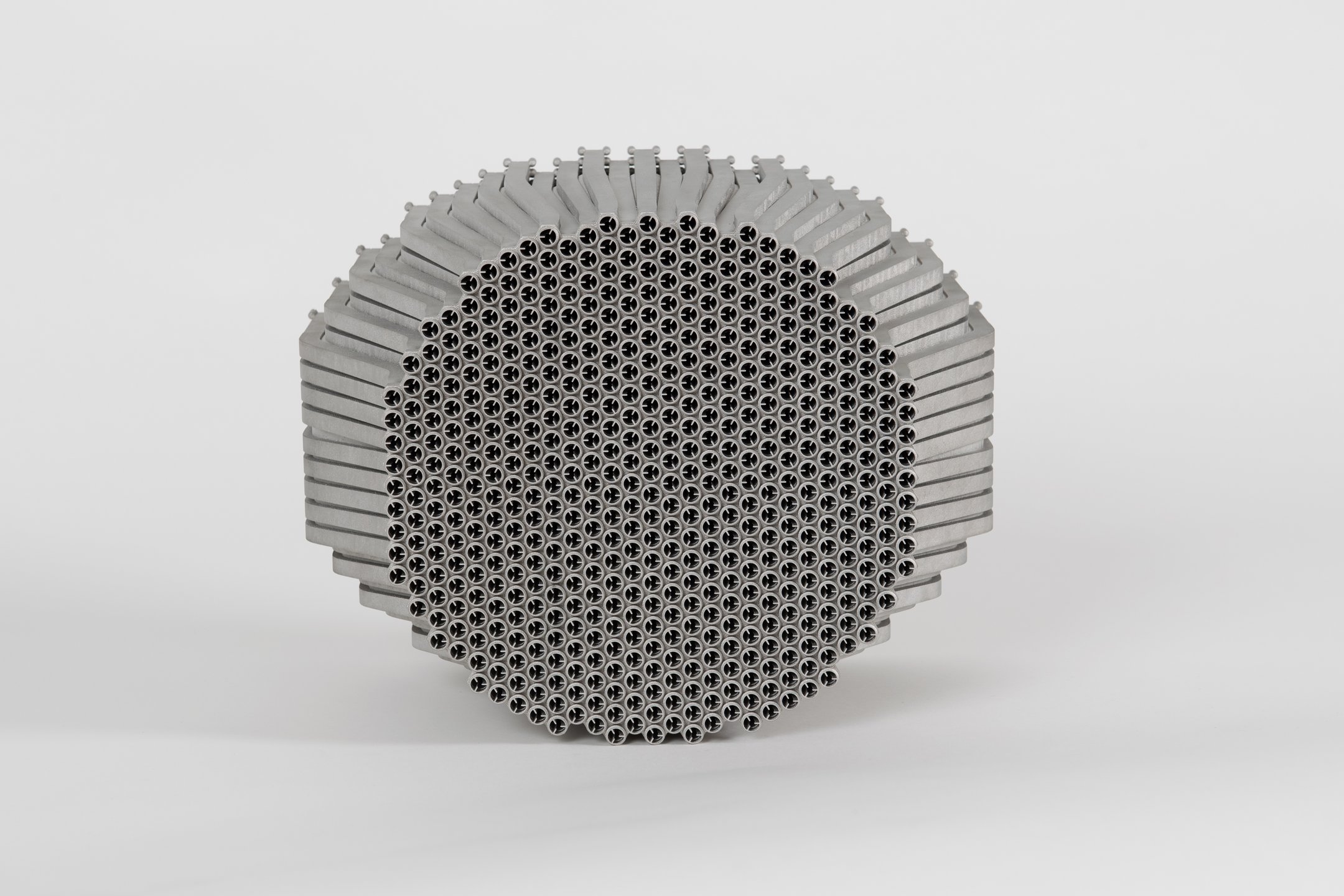

SWISSto12 makes strategic investment in four Additive Industries MetalFabG2 printers to build next-generation RF products

Founded in 2011 as a spin-off from the Swiss Federal Institute of Technology in Lausanne (EPFL), SWISSto12 gained international recognition for its innovative use of precision manufacturing and 3D printing in developing next generation RF products. The company has developed the world’s largest IP portfolio for the use of 3D printing in RF product applications, relying…

MetalFAB 300 Flex: The Most Flexible & Affordable Solution in Metal Additive Manufacturing

At Additive Industries, we are committed to driving the adoption of large systems by mitigating the risks associated with adoption and expanding the horizons of industrial applications. Our solution lies in revolutionizing the…