Beckhoff enables compact, maintenance-friendly robot design

b+m surface systems GmbH, based in Eiterfeld in Germany, plans and builds complete painting systems – encompassing the process, conveyor, and application technology. The company’s extensive expertise results in particularly application-oriented solutions. This is exemplified by the 6-axis articulated robots from the T1 X6 and T2 X6 series, which have been specially optimized for paint application…

Yizumi Germany: Simplified engineering with the MX-System

Yizumi Germany GmbH specializes in applications for the additive manufacturing sector. At the innovation center in Alsdorf near Aachen, this Yizumi Group company relies on the MX-System to execute complex 3D printing projects. This modular, control cabinet-free system provides flexible, scalable automation, reduces engineering costs, and thus shortens project lead times. Watch…

Gelijkstroom: steeds vaker een concrete toepassing

In onze reeks over de (her)nieuw(d)e aandacht voor gelijkstroom kijken we naar de praktisch toepasbare keuzes in industriële projecten. Want terwijl nieuwe energiebronnen en slimme netoplossingen elkaar snel opvolgen, groeit ook de vraag of het huidige wisselstroomsysteem nog altijd de meest logische basis vormt. Lees verder [Bron: industrievandaag.nl]

Advanced Engineering: A flexible, modular cell system

Advanced Engineering (AE) is a globally active, family-run technology company that provides machines for the semiconductor and PCB industry. In this video, Lukas Moser, CEO, explains their latest innovation: a flexible, modular cell system for transporting PCBs. The integrated MX-System increases installation speed and flexibility while making electrical planning much easier. Watch…

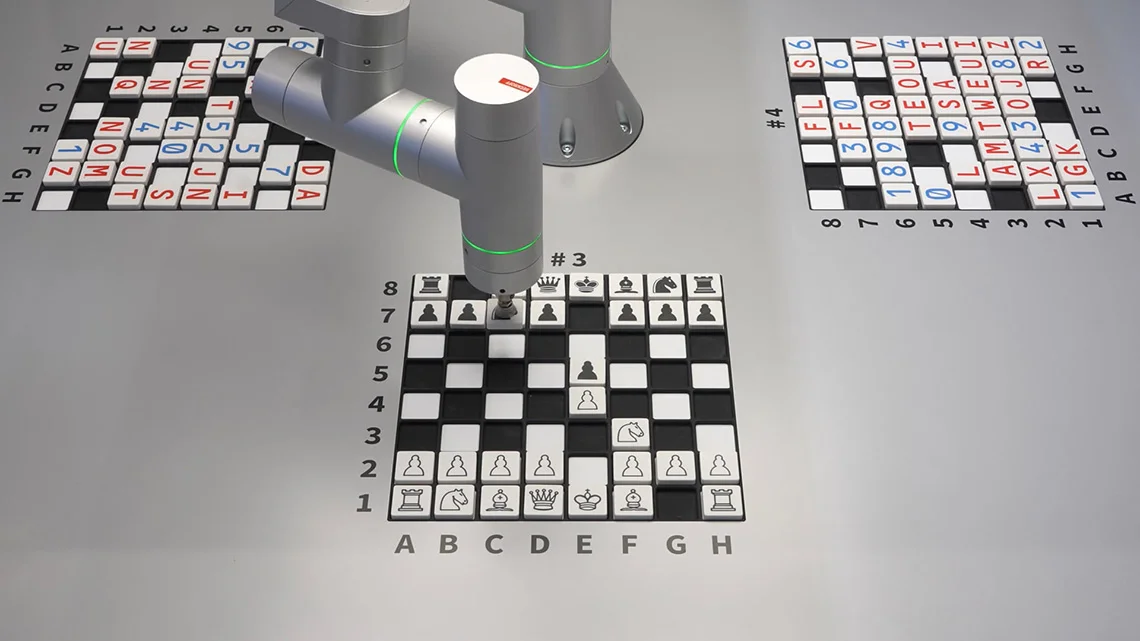

Physical AI with TwinCAT CoAgent for Operations

An industrial robot programmed by voice command – made possible by TwinCAT CoAgent for Operations. TwinCAT CoAgent provides various agents that use the Model Context Protocol (MCP) to enable users to interact directly with the machine using questions or commands. This AI agent translates natural language into executable processes, orchestrates control, planning, and diagnostics in real…

Beckhoff introduceert AM1000 economy servomotoren

Beckhoff, een toonaangevende speler in de automatiseringssector, heeft onlangs de AM1000-serie economy servomotoren gelanceerd, een compacte en betaalbare oplossing voor dynamische positioneringstaken in de industrie. Deze nieuwe reeks motoren, gemaakt in Duitsland, combineert hoge prestaties met een aantrekkelijke prijs-kwaliteitverhouding. Beschikbaar in internationale flensmaten van 40, 60 en 80 mm, biedt de AM1000 een veelzijdige optie voor machinebouwers en systeemintegratoren die…

Advanced Engineering: A flexible, modular cell system

Advanced Engineering (AE) is a globally active, family-run technology company that provides machines for the semiconductor and PCB industry. In this video, Lukas Moser, CEO, explains their latest innovation: a flexible, modular cell system for transporting PCBs. The integrated…

Innovations and AI in automation

In this video, we talk to Hans Beckhoff, founder, owner, and Managing Director of Beckhoff Automation, about the development of product innovations from the early days to the present, the role of artificial intelligence in automation, and the latest innovations in…

Decentralized and control-cabinet free automation

The decentralized MX-System is the first to achieve completely control cabinet-free automation of machines and systems. To this end, Beckhoff has bundled over four decades of automation expertise into a modular system that performs all of the tasks and exhibits the properties of a classic control cabinet. Read more

Precise synchronization with PC-based control

Grob-Werke, a family-owned company founded almost 100 years ago, is introducing their new aluminum 3D printer. In this video, Christoph de Pay, product manager for Additive Manufacturing at Grob-Werke, highlights possible applications in the electromobility sector and describes the key functions…