Customized coil solutions

KUK serves automotive customers in Europe and Asia, providing customized coil solutions through our in-house expertise in winding, connecting, and assembly. Read more [Picture source: KUK Coils on linkedin.com]

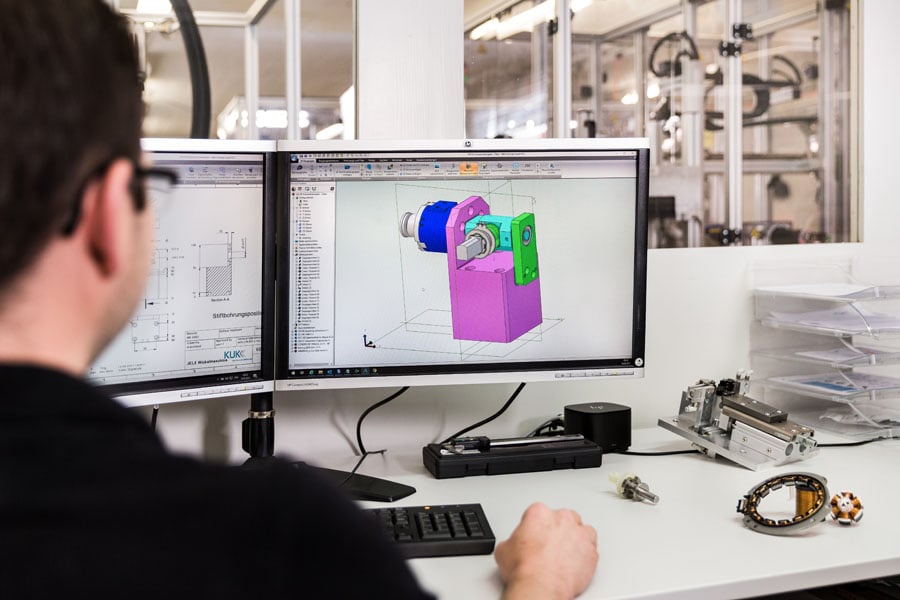

How to prepare a complete specification for a solenoid coil

The basis for the successful production of solenoid coils is a CAD drawing as well as a proper layout of the most important parameters. In order to make rapid progress in product development, it is important that the essential requirements for a customer-specific coil are specified. Read more

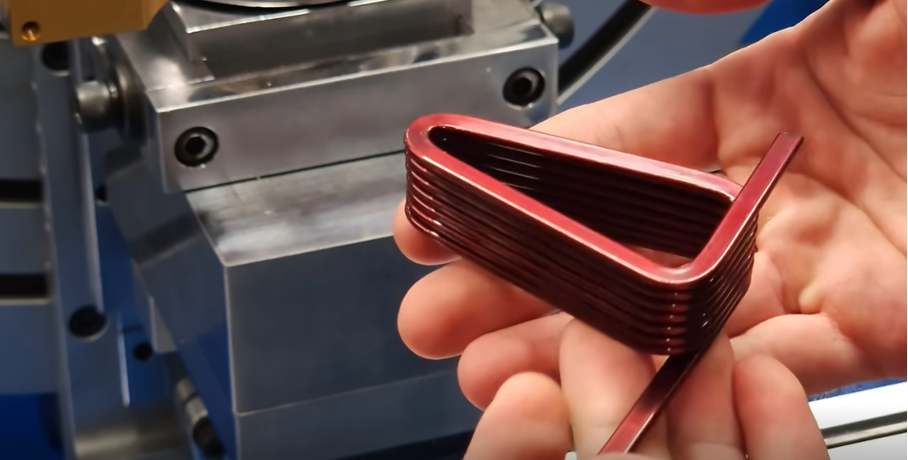

Edgewise or ‘other’wise?

Wire doesn’t always have to be round. In fact, flat wire is becoming more and more popular for inductive components. With edgewise winding techniques, engineers can achieve significantly higher filling factors. [Picture source: KUK Wijdeven on linkedin.com]

Een tweede leven voor medische apparatuur

Soms ligt er waardevolle apparatuur stof te verzamelen, terwijl dit nog ingezet kan worden voor de zorg. Dankzij de vrijgevigheid van Medisch Spectrum Twente en Adviseur Elektra van het MST Louis Wesselink, hebben wij 40 isolatiewachters retour mogen ontvangen die een nieuwe bestemming gaan krijgen. Lees verder [Picture source: Kuk Wijdeven…

Insulation layer on magnet wires: A common stumbling block for engineers

In coil production, the insulation of the wire has an influence on a wide variety of product properties such as application range, service life, costs or coil design. Wire insulation also has an effect on various factors during coil manufacturing, such as scrap or further processing. This article summarises the essential facts about wire insulation –…

Coil development for and with the customer

Coil development is an important process that requires careful planning to achieve the desired performance and reliability. During the feasibility phase, experienced coil manufacturers understand the challenges that may arise. The cooperation with a customer-specific coil manufacturer during the feasibility phase and for sampling is of great importance. Read more

Looking at this micro air coil, it is unsurprising that the biggest challenge is the dimension

In the drawing, manufacturing may seem quite feasible, but the reality is often different. That is why it is worth involving an experienced coil manufacturer at an early stage in such projects. Read more [Picture source: KUK Coils on linkedin.com]

Prototype in 24 Hours? Challenge accepted!

For engineers and R&D teams, speed can be the difference between leading and following.At KUK Wijdeven, our in-house protoshop delivers prototypes fast, so you can validate designs, test concepts, and move forward with confidence. Read more [Picture from…

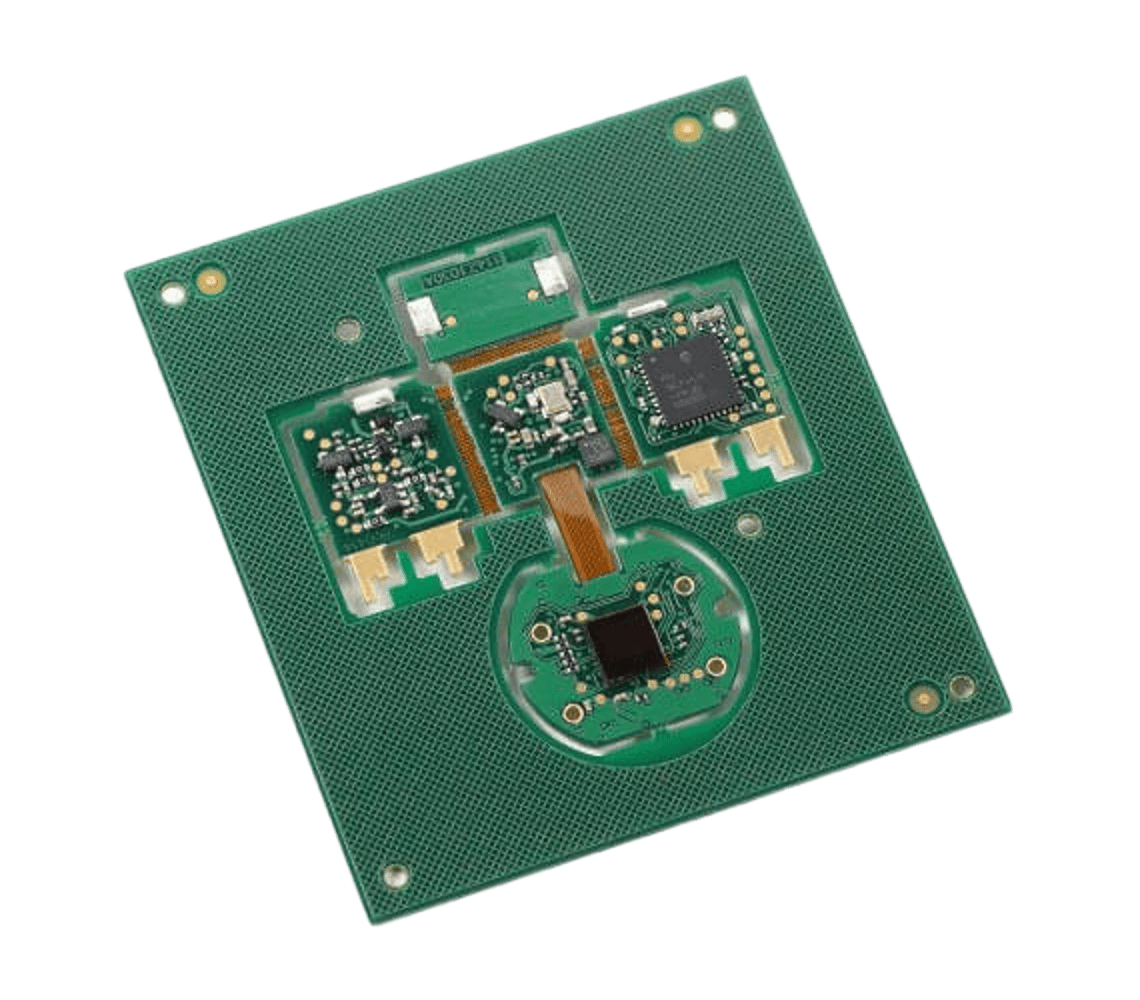

SMD assemblage van klantspecifieke PCB

Op onze volautomatische Surface Mount Device lijnen (SMD) verzorgen wij voor u de PCB assemblage. Diverse soldeersystemen vervolledigen ons aanbod op het gebied van SMD PCB assemblage. Lees meer

Edgewise Windings offer benefits, but also design challenges

Edgewise windings offer clear advantages for certain high-performance applications. However, despite their growing popularity, it’s important not to overlook the potential drawbacks. These should be carefully evaluated during the design phase to ensure optimal results. More in this article [Picture source: KUK Wijdeven on linkedin.com]