MODUS™ IM Equator software

Introducing the MODUS™ IM Equator software, the latest innovation from Renishaw. Designed to maximise productivity for Equator™ gauging system users, this software is a game-changer for intelligent metrology programming. Read more [Picture source: Renishaw Benelux B.V. on linkedin.com]

Stainless steel tape scale with significant installation benefits

RTL FASTRACK™ is a market proven track-mounting system that is quick and easy to install. If damaged, the scale can be pulled out of the guide rails and quickly replaced, thus reducing machine downtime. Read more [Picture source: Renishaw Benelux B.V. on linkedin.com]

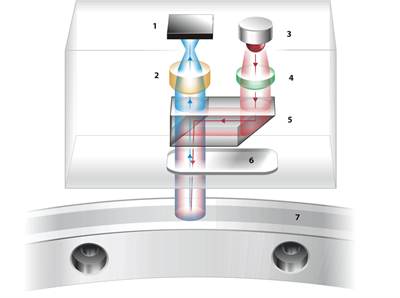

FORTiS™ enclosed optical encoders for machine tools

Renishaw provides an extensive range of enclosed optical encoders, also known as sealed encoders. Learn how our absolute measurement technology, along with robust sealing and a non-contact design, can enhance precision manufacturing in harsh environments such as machine tools. Read more

Safety first – the position determination and checking algorithms of the RESOLUTE™ true-absolute optical encoder

This white paper gives an overview of the operation of the RESOLUTE absolute encoder and describes in detail the safety aspects of its position determination and checking algorithms. Read more

Industrial robot calibration and maintenance solutions

A range of calibration and maintenance tools to enhance the accuracy and productivity of robots within industrial automation. Achieve fast, consistent robot cell programming and set up processes with traceable performance measurement. Lees meer [Bron foto: Renishaw plc op renishaw.com]

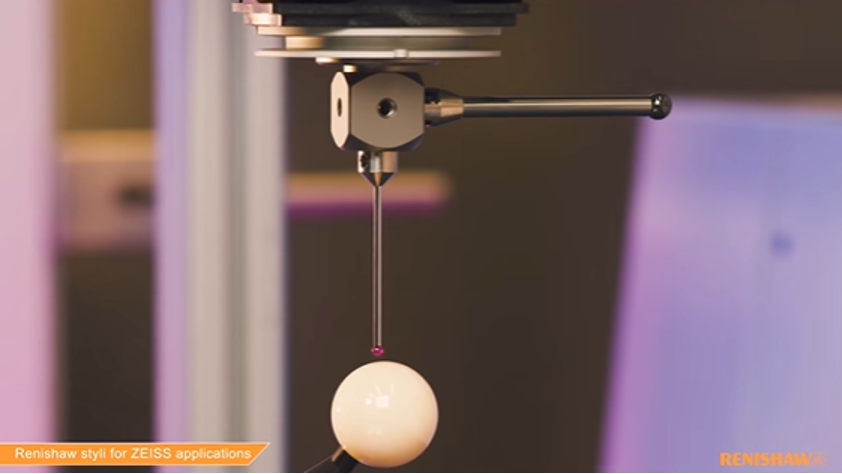

Did you know Renishaw has a comprehensive range of styli compatible with ZEISS probe heads?

As a supplier of probe systems for selected ZEISS CMMs, Renishaw has increased its range so users can benefit from the high precision specifications associated with all Renishaw styli. Read more [Picture from video by Renishaw Benelux…

Shop floor metrology for modern manufacturing

8 ways shop floor metrology is transforming modern manufacturing. Read more

Creating “the world’s most beautiful bicycle” with additive manufacturing

Global engineering company, Renishaw, has collaborated with J.Laverack Bicycles on the development of a luxury bespoke bike. Together, the companies have developed bespoke titanium lugs and components which pair to corresponding carbon fibre parts to create a first-of-its-kind road bike, the J.Laverack Aston Martin .1R. Described as the world’s most bespoke, most advanced and most meticulously…

Renishaw helps Cookson Industrial make world’s most expensive metal viable for additive manufacturing

Using precious metals in additive manufacturing (AM) provides new ways to utilise these materials’ unique properties. However, the high cost of these metals means that large-scale production is often beyond the reach of many manufacturers. To address this challenge, Renishaw helped precious metal AM pioneers, Cookson Industrial, succeed in making the production of platinum rhodium parts…

Data is key to achieving manufacturing process control

Many Equator™ gauging system customers benefit from an integrated machine tool solution using Renishaw’s Intelligent Process Control (IPC) software. Read more [Picture source: Renishaw Benelux B.V. on linkedin.com]