De AxiSet™ Check-Up is een voordelige oplossing om de nauwkeurigheid van rotatieassen te controleren en te verbeteren

De AxiSet Check-Up biedt een gemakkelijke en betrouwbare methode om de nauwkeurigheid van rotatieassen te analyseren en problemen door onjuiste machine-instellingen, botsingen of slijtage te identificeren. In slechts enkele minuten kunnen gebruikers van meerassige bewerkingscentra en multi-tasking machines de fouten in uitlijning, geometrie en middelpunten opsporen die mogelijk de oorzaak zijn van lange insteltijden en producten…

ADTpro-100 is an advanced handheld, standalone encoder diagnostic tool

It works across selected Renishaw incremental optical encoders, including both analogue and digital readheads. Read more [Picture source: Renishaw Benelux B.V. on linkedin.com]

Equator-X™ 500 gauge: two systems in one

The new Equator-X dual-method gauging system brings unique capability to the shop floor with its dual measurement functionality; Absolute and Compare. Users can select the optimum inspection mode for their process challenge, effectively deploying two systems in one. Read more

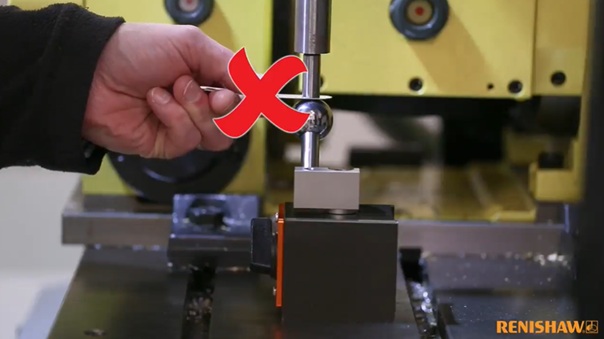

Handmatige kalibratiestappen voor meettasters elimineren

Handmatige kalibratiemethodes voor meettasters kunnen tijdrovend zijn en vaak foutgevoelig en inconsistent, wat de kwaliteit van volgende metingen beïnvloedt. ASC-1 helpt u maximale meetnauwkeurigheid op uw bewerkingsmachines te bereiken door handmatige kalibratiestappen voor meettasters te elimineren. Lees verder

Welk geavanceerd NC4-laser toolsysteem is geschikt voor u?

De keuze van het juiste NC4-laser toolsysteem hangt af van uw machine, configuratie, ruimtebeperkingen en prestatie-eisen. Onze vaste NC4+ Blue-systemen zijn compact en ruimtebesparend, ontworpen voor kleine machineopstellingen en zorgen ervoor dat er geen interferentie is met bewerkingen. Het gebruik van de eerste blauwe…

Thinking about getting started with additive manufacturing? Start with the right insights

Our guide to additive manufacturing brings together everything you need to explore the possibilities of additive manufacturing (AM). Read more [Picture source: Renishaw on linkedin.com]

Wat is RENGAGE™-technologie?

RENGAGE™-technologie combineert beproefde silicium rekstrook-technologie met ultracompacte elektronica, waardoor probesystemen op machines uitstekende 3D-meetmogelijkheden en een herhaalbaarheid tot op submicronniveau bieden. Lees verder [Bron foto: Renishaw Benelux B.V. op linkedin.com]

Op zoek naar lange lineaire encoders voor grote machines?

Renishaw biedt nu nieuwe, langere FORTiS™-encoders met afgedichte schaal, perfect voor grotere machine-toepassingen. Lees verder [Bron foto: Renishaw Benelux B.V. op linkedin.com] FOTO:

Wilt u de manier waarop u assemblages inspecteert verbeteren?

Ons PHS-2 systeem is ontworpen voor veeleisende ‘body-in-white’-metingen, waarbij een nauwkeurige hoekpositie en een groot bereik essentieel zijn.De servo-positioneringskop kan in twee assen naar een oneindig aantal posities worden verplaatst, waardoor de flexibiliteit en toegankelijkheid worden vergroot. Lees verder [Bron foto: Renishaw Benelux B.V. op linkedin.com]

QC20 ballbar voor verificatie van bewerkingsmachines

De Renishaw ballbar om de prestaties van bewerkingsmachines te verifiëren wordt in de industrie zeer gewaardeerd om zijn snelheid, eenvoud en effectiviteit, en is dan ook een vertrouwde keuze. Lees meer