AGILITY® CMM’s met 5-assige technologie

AGILITY® CMM’s brengen REVO® Snelheid, nauwkeurigheid en flexibiliteit van 5-assig meten naar de werkvloer en het lab, met de productiekwaliteit en innovatieve technologie van Renishaw. Lees verder en bekijk de video

Custom 3D printed styli

Metal additive manufacturing (AM) is used to create parts which cannot be made using traditional manufacturing methods. The flexibility in design means additively manufactured styli can be created and customised for almost any application. Watch the video

TEMPUS™ technology: build twice as fast, with no compromise on part quality

TEMPUS technology is a new scanning algorithm for the RenAM 500 series of metal additive manufacturing (AM) systems, which delivers a substantial increase in AM productivity without compromising on part quality. This technology allows the system lasers to fire whilst the powder recoater is moving, removing up to nine seconds of build time from every layer. With builds frequently containing thousands of…

Enhancing micro-milling precision with FORTiS-N™ enclosed encoders

Anderson Europe (Anderson) GmbH has been producing high-precision CNC-controlled machines for over six decades. It started with PCB drilling machines — as Germany ramped up its PCB production in the late 1950s — and expanded to include complete turnkey solutions for various industries including semiconductor and automotive. The company prides itself on excellent customer service and…

Meetoplossingen voor industriële automatisering

Integreer een vaste meetoplossing in uw robotcel om de tussenkomst te minimaliseren, en pas meten in het proces toe voor uw industriële automatisering. Lees verder

RMP24-micro: the world’s smallest wireless machine tool probe

Improve the accuracy and efficiency of your machining process with the world’s smallest wireless probe for machine tools. Discover our miniature machine tool probe for automated workpiece set-up and inspection on compact machining centres. Read more

Renishaw encoders go under the 3DHISTECH microscope

Renishaw’s Zsombor Zelena collaborates with 3DHISTECH Ltd, a pathology equipment and services specialist, to provide them with the latest in encoder technology. Watch the video summary and read the full article for further information and links.

Renishaw brings additive manufacturing AM innovation to Olympic track bike components

Speed, balance and aerodynamics are integral to the rider’s performance, so when designing a new track bike for the Paris 2024 Olympic Games, the British Cycling team considered how different manufacturing methods could achieve performance…

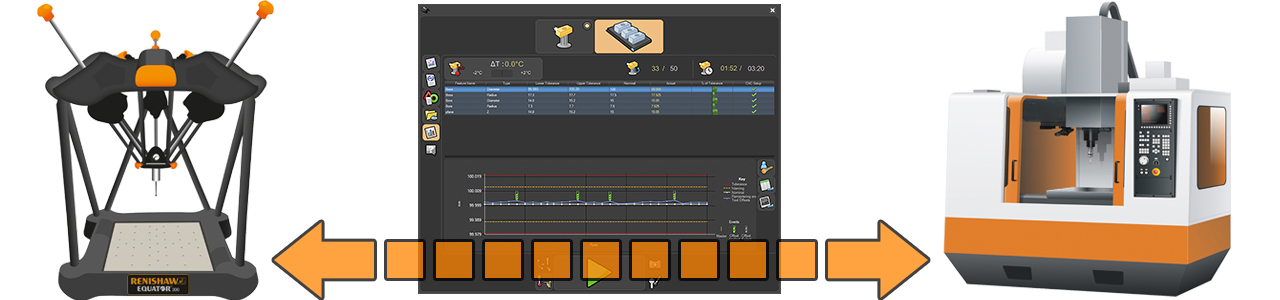

IPC intelligent process control

Process control can be achieved with closed-loop feedback using Equator™ gauging data to update offsets directly on machine tool controls. Read more

AGILITY® CMM’s zijn gebaseerd op 50 jaar innovatie

Onze serie AGILITY CMM’s is ontworpen voor maximale doorloopsnelheid met behoud van hoge nauwkeurigheid, voortbouwend op onze uitstekende reputatie op het gebied van innovatie in de meest veeleisende industriële sectoren. Lees verder [Bron foto: Renishaw Benelux B.V. op linkedin.com]