SCHUNK Engineering – Innovating Partnerships

Discover how SCHUNK combines decades of expertise in clamping, gripping, and automation with a proven engineering process to create tailor-made solutions. From project management to design, manufacturing, assembly, and after-sales service, SCHUNK delivers custom pneumatic, mechatronic, and robotic accessory systems that…

Improving process quality in semiconductor wafer inspection with the XM-60 multi-axis calibrator

Certain Micro Application Technology (CMAT) manufactures precision probe cards for semiconductor processes. CMAT was looking for machine calibration solutions to monitor equipment status and ensure optimal operation to meet customer demands. Watch the video

Take precision to new places

The Absolute Arm is built to operate flawlessly in demanding industrial conditions. Watch how it delivers effortless operation and outstanding efficiency in a foundry, whether laser scanning with the Absolute Scanner AS1 or using tactile probes. Watch…

Hoe blijf je als toeleverancier relevant in een razendsnel veranderende markt?

De Nederlandse semiconindustrie staat aan de vooravond van een nieuwe groeifase. Koplopers zoals ASML bereiden zich voor op een forse opschaling en die beweging raakt de hele keten. Voor toeleveranciers betekent dit: scherp schakelen, strategisch investeren en nú keuzes maken die morgen het verschil maken. Op donderdag 4 september brengt Brainport Development besluitvormers uit de gehele semicon supply chain samen. Een compacte,…

maxon acquires strategic minority stake in Synapticon

![]()

The Swiss maxon Group is expanding its expertise in the field of motion control through a strategic partnership with the German company Synapticon. The goal of the collaboration is the joint development of high-performance drive solutions with integrated functional safety, based on optimally combined components from both companies. Read more

Robots geven boost aan welzijn boer en koe

Met 1.000 taartjes vierde groene groeier Lely de bekroning met de Rotterdamse Ondernemersprijs 2025. Feest op de campus in Maassluis. Het is een award voor grensverleggend en maatschappelijk betrokken ondernemerschap. “Dat is precies waar het bij ons om draait,” zegt CEO André van Troost. “Met innovaties problemen in de landbouw tackelen, maar vooral kansen benutten. Dat doen we als familiebedrijf…

Altair welcomes UVIRESO SPACE to the Altair Aerospace Startup Accelerator Program (ASAP)

The UVIRESO team develops advanced spacecraft thruster solutions and uses ASAP to accelerate design, testing, and optimization workflows. Through the program, they access Altair’s simulation tools and expertise to bring propulsion technology to market faster. Ready to accelerate your aerospace startup? Learn more [Picture source: Altair on linkedin.com]

What do 900+ semiconductor tools across 65 fabs on 4 continents have in common?

They’re all powered by Agileo Automation!From North America to Europe and Asia, Agileo Automation delivers cutting-edge control and connectivity software to some of the most advanced players in semiconductors, electronics, and industrial manufacturing – often without ever setting foot on site. Read more [Picture source: Agileo Automation on linkedin.com]

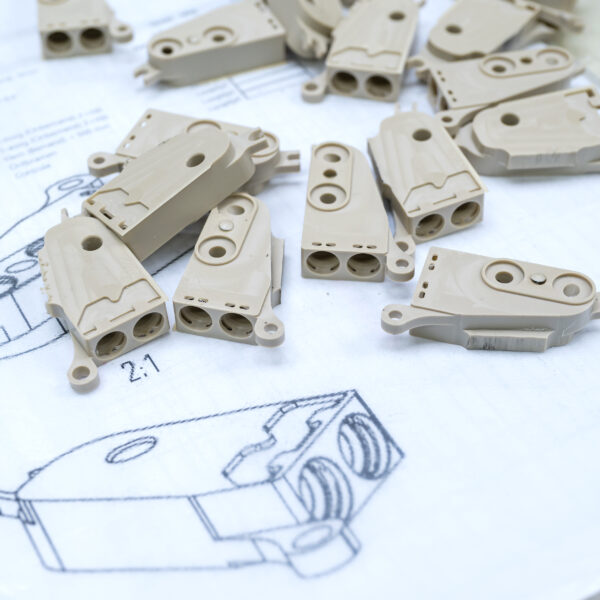

Waarom metaal steeds vaker plaats maakt voor kunststof

Wat als het materiaal dat je al jaren gebruikt, eigenlijk niet meer het meest logisch is? Metaal is lang de norm geweest in technische toepassingen voor vele sectoren, maar achter de schermen heeft kunststof de afgelopen jaren veel terrein gewonnen. Wat zijn de voordelen van kunststoffen? Is dit een structurele verschuiving? En wat moet je weten…

Bij TEVEL ontwerpen en produceren we industriële, in hoogte verstelbare werktafels

Onze robuuste werktafels zijn ontwikkeld om zware lasten moeiteloos te dragen, terwijl ze tegelijkertijd zorgen voor een ergonomische en comfortabele werkhouding. Lees verder [Foto uit video van TEVEL op linkedin.com]