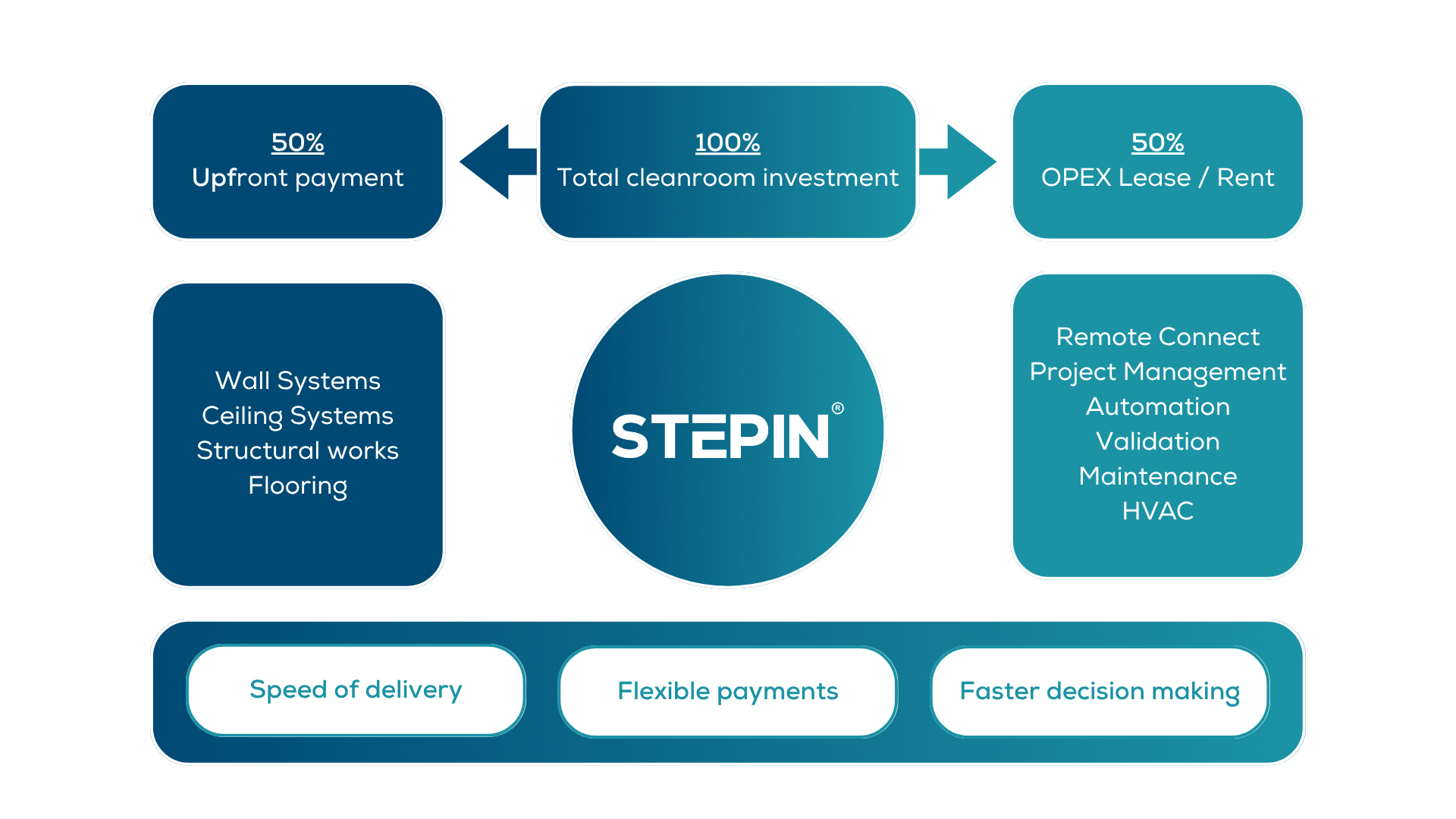

StepIn®, a strategic approach to financing cleanroom infrastructure

At ABN Cleanroom Technology, we believe that access to advanced cleanroom environments should not be limited by financial barriers. Controlled environments are essential for industries that shape the future, from life sciences and healthcare to advanced manufacturing and microelectronics. Yet many organizations face significant challenges when trying to realize these critical facilities.

Renovating and upgrading cleanrooms has often been a complex and disruptive process. At ABN Cleanroom Technology, we understand the challenges involved—balancing compliance, operational continuity and scalability. That’s why we have partnered with Poels Labs to introduce NUVION, a groundbreaking cleanroom…Cleanroom renovation & upgrades

Commissioning, Qualification and Validation

At ABN Cleanroom Technology, we recognize that the successful implementation of a cleanroom facility depends on a well-structured, thoroughly planned approach. Our process covers every phase of the project, from initial process mapping to final validation and continuous monitoring, ensuring all aspects meet the highest industry standards. Quality risk management is central to our services, playing a…

ABN Cleanroom Technology ontwikkelt mobiel labo voor Einsteintelescoop

ABN Cleanroom Technology en Poels Labs bouwden een mobiel laboratorium waarmee lokale en internationale bedrijven onderdelen kunnen reinigen en testen voor de Einsteintelescoop. Dit innovatieve project, gesteund door het ET-innovatiefonds van POM Limburg en het provinciebestuur, opent internationale deuren en geeft innovatie in de regio een stevige impuls. Lees verder [Bron: pomlimburg.be]

NUVION: Cleanroom renovations redefined

Renovating cleanrooms has historically posed significant challenges, often caught between temporary solutions and inefficient traditional approaches. In response, ABN Cleanroom Technology and Poels Labs have introduced NUVION, an innovative concept designed to streamline the renovation process while prioritizing compliance, know-how, and efficiency. By integrating the engineering expertise of the ADAPTUS platform with the specialized craftsmanship of…

Timelapse video capturing the construction of LionVolt’s 3D Anode pilot production line at BIC1 in Eindhoven

We’re happy to share a timelapse video capturing the construction of LionVolt’s 3D Anode pilot production line at BIC1 in Eindhoven. This video showcases the build process of the complete dryroom, from the external structure to the integration of the equipment.

SRBA Controlled Environments and ABN Cleanroom Technology join forces on 3D printing cleanroom

The facility employs a modular SRBA wall and ceiling system, providing flexibility for future upgrades. This design choice supports ABN’s productised cleanroom approach, making the space adaptable to changing requirements. Overall, this project reflects the synergistic approach of these companies in combining their expertise for industrial advancements with sustainability in mind. Read more [Source: cleanroomtechnology.com]

Successful collaboration: ABN Cleanroom Technology NV and SRBA Group deliver KMWE a next-gen cleanroom

A few months ago, KMWE and their subsidiary ATM Oirschot signed an agreement to design and construct an ISO7 & ISO6 cleanroom at their new 3D and repair facility at Brainport Industries Campus. This project is realized by SRBA Group in partnership with ABN Cleanroom Technology NV. We are excited to announce the successful completion of…

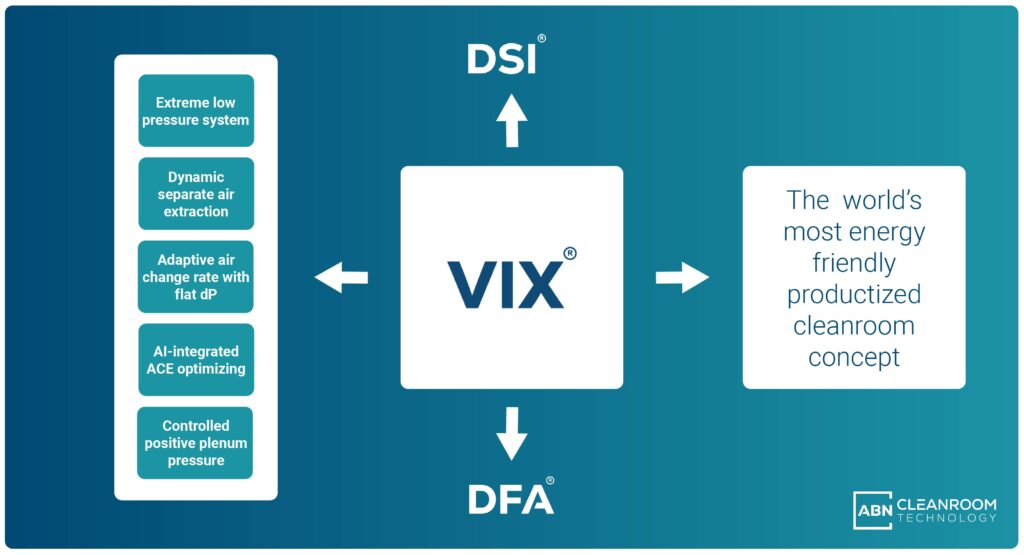

VIX: Energiebesparing en innovatie, nu fiscaal aantrekkelijk via de EIA

Fantastisch nieuws voor onze klanten in Nederland: ons innovatieve en energiezuinige VIX-concept is officieel erkend binnen de Nederlandse Energie Investeringsaftrek (EIA)! Dit betekent dat bedrijven die kiezen voor VIX nu niet alleen bijdragen aan een duurzamere wereld, maar ook aanspraak kunnen maken op aantrekkelijke fiscale voordelen. Lees verder

ABN Cleanroom Technology strengthens growth ambitions with acquisition of POELS NV

ABN Cleanroom Technology and POELS have long collaborated on innovative projects, including the development of the circular wall system HOSPIWALL for the hospital sector. The acquisition of POELS NV by ABN Cleanroom Technology further expands the construction expertise in cleanroom wall and ceiling systems. Read more