The Power of Automation in Additive Manufacturing | Sauber Technologies Case Study

Discover how Sauber Technologies leverages the MetalFAB metal 3D printer to not just cut lead times and lower labor costs, but to redefine the very essence of quality control in Additive Manufacturing.

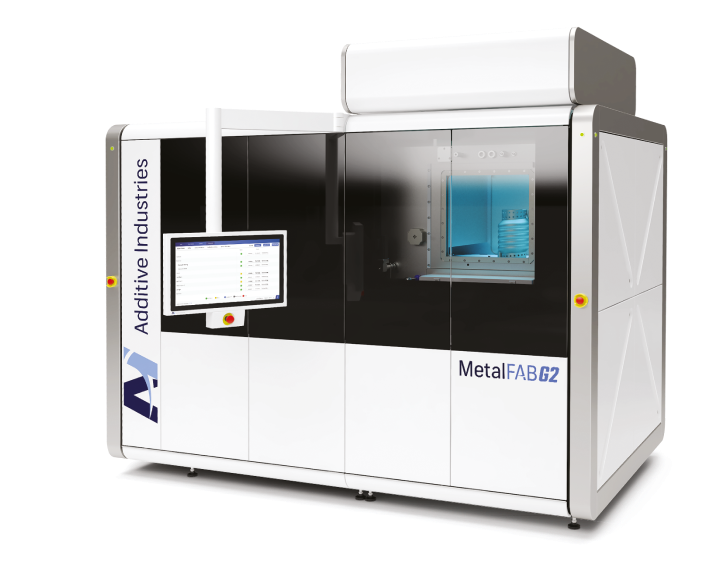

Spotlight on our MetalFABG2!

Proven to offer continuous production through automation, driving down costs in aerospace, high tech, energy, automotive, and more. The MetalFABG2 is redefining precision and efficiency in metal additive manufacturing. What makes it so unique?• Modular design for easy scalability• Automated laser calibration for precise results• Continuous production to meet your demands• Design flexibility for creative possibilities• Minimize downtime with efficient operation• Ensure…

Additive Industries empowers VDL with MetalFABG2 metal 3D printer

VDL ETG, a leader in the design, production, and realization of sophisticated mechatronic systems, has taken an ambitious step forward. The Eindhoven-based firm announces its latest acquisition: the MetalFABG2 3D metal printer from Additive Industries. This new collaboration symbolizes VDL ETG’s relentless pursuit of innovation, especially in an age where precision and efficiency are paramount.

Interview with Kartik Rao, Strategic Marketing Director at Additive Industries

Additive Industries is a manufacturer of metal 3D printers. Their flagship printer, the MetalFABG2, is the most automated metal printer on the market. The company also generates software and material parameter sets to complement its printer sales and supports its customers with a range of consultancy and training offering for workforce development. Additive Industries has three locations, its headquarters in…

Case study: Design & Manufacture of AM F1 Chassis Inserts

This case study demonstrates how the Alfa Romeo Racing ORLEN F1 team is utilizing the capabilities of additive manufacturing to produce essential titanium Ti6Al4V chassis inserts for their F1 race car. The entire process, from design to assembly and testing, is presented, showcasing the immense value that AM has brought to this crucial F1 component. In…

ADDDAM selects Additive Industries’ 3d metal printer MetalFABG2 for expansion in the automotive and machine engineering industry

3D metal printer manufacturer Additive Industries installed its MetalFABG2 3D metal printer at ADDDAM, a volume flexible metal processing and production solutions supplier. The printer has been installed at ADDDAM’s facility in Brixen, making it Additive Industries’ first customer in Italy. Read more [Source: adddam.com]

Still using traditional manufacturing methods?

Upgrade to the MetalFABG2 and tap into the potential of automated metal additive manufacturing for your large production needs. – Modular design for easy scalability– Automated laser calibration for precise results– Continuous production to meet your demands– Design flexibility for creative possibilities– Minimize downtime with efficient operation– Ensure safe operation for your team Unlock the future of manufacturing with the…

Volkswagen Group Expands Additive Manufacturing Capabilities with Additive Industries’ MetalFAB System

In 2018, Volkswagen established a 3D printing center to produce intricate automotive components using various 3D metal printing technologies. Additive Industries’ MetalFAB system has been instrumental in Volkswagen’s additive manufacturing success, enabling the production of metal components and earning recognition with a prestigious award. Read more