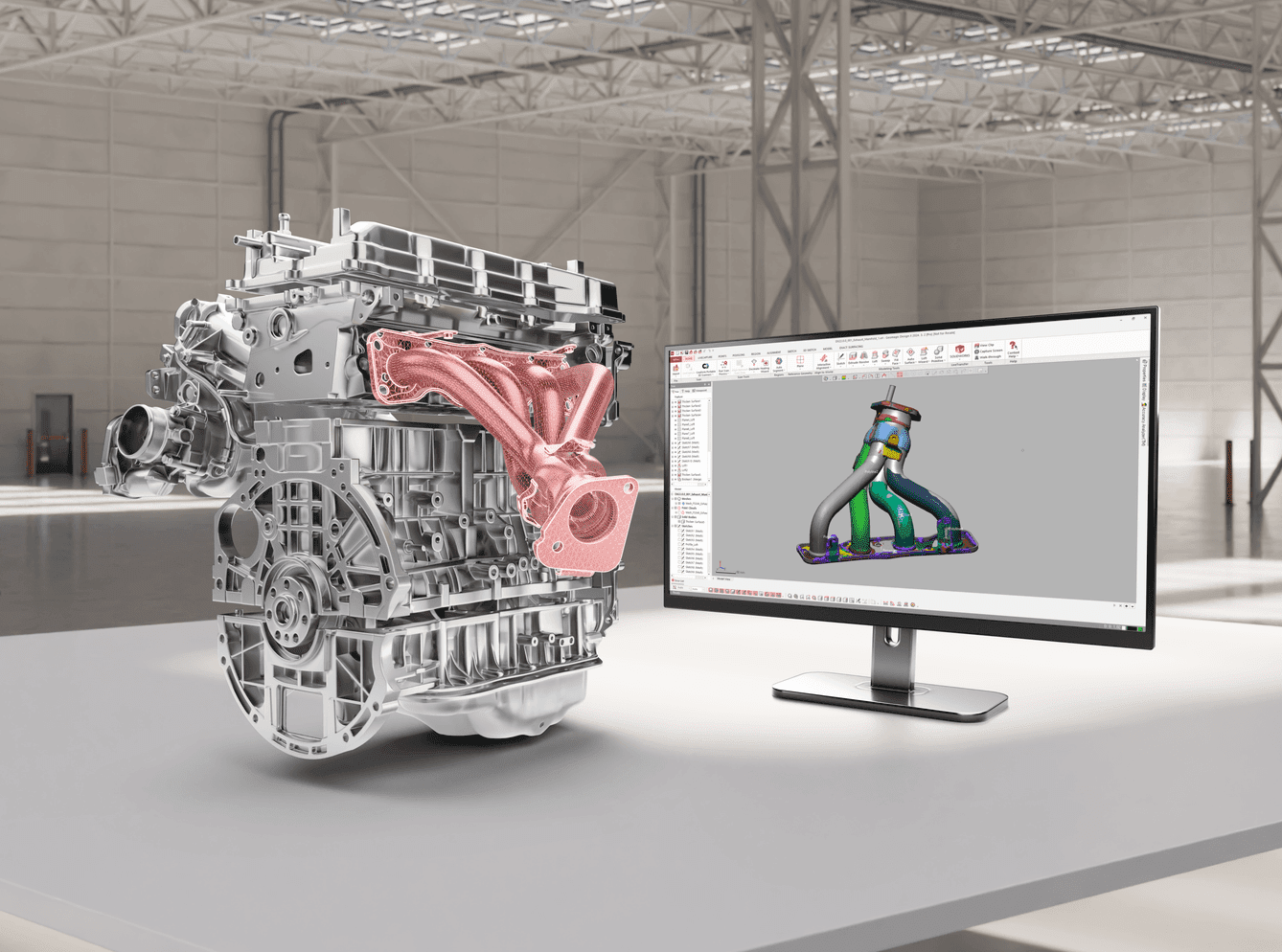

Red Bull Ford Powertrains uses

Hexagon technology to ensure super-high-performance of its first-ever F1™ powertrain Hexagon’s advanced measurement technologies have played a crucial role in the development of the all-new Red Bull Ford Powertrain, built to meet the demanding new 2026 F1™ regulations for smaller, lighter, more nimble cars and increased on-track competitiveness. Read more

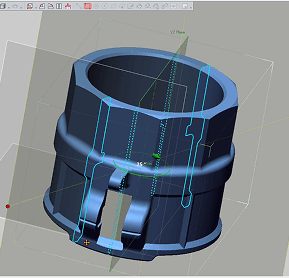

Professional, accessible reverse engineering

Scan, process and create accurate CAD models easily with the ATLASCAN Pro + Geomagic Design X Go bundle. Read more

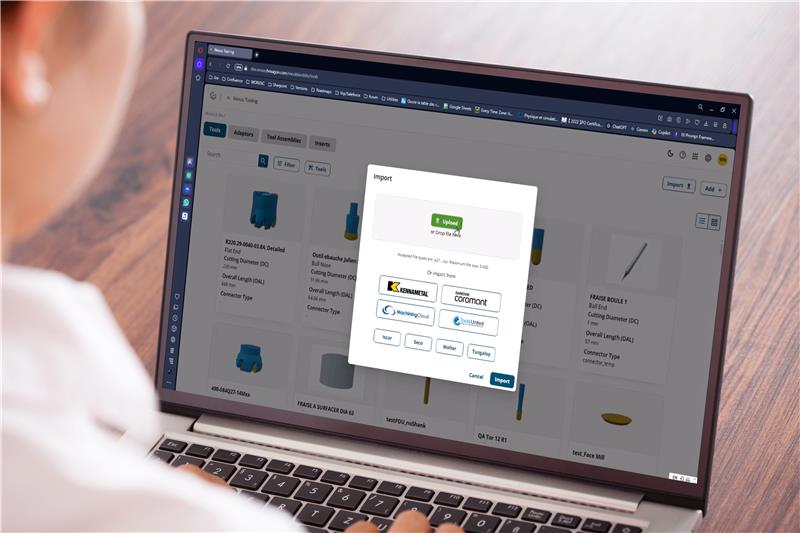

Why your tooling library data is the first step to real manufacturing automation

Walk into any machine shop today and you’ll hear the same pressure points: tighter deadlines, rising part complexity, a stubborn skills shortage and customers expecting “digital-ready” suppliers who can turn work around without delay. It’s no surprise, then, that artificial intelligence has become the industry’s newest beacon of hope. Read more

Closing the gaps in the digital thread

In manufacturing, precision is everything. From the initial design to the final inspection, every step is built on a foundation of accurate data. The ideal scenario is a seamless flow of information – a “digital thread” that connects every stage of the product lifecycle. This thread ensures that the part you inspect is the exact part…

Inspire 2025.2

https://www.youtube.com/watch?v=gdaHnnH9Gys

This new release brings 134 enhancements and improvements designed to make measurement workflows faster, smarter, and more reliable. We’ve strengthened GD&T analysis, expanded automation, improved device support, and delivered significant performance gains across the platform. Watch the video

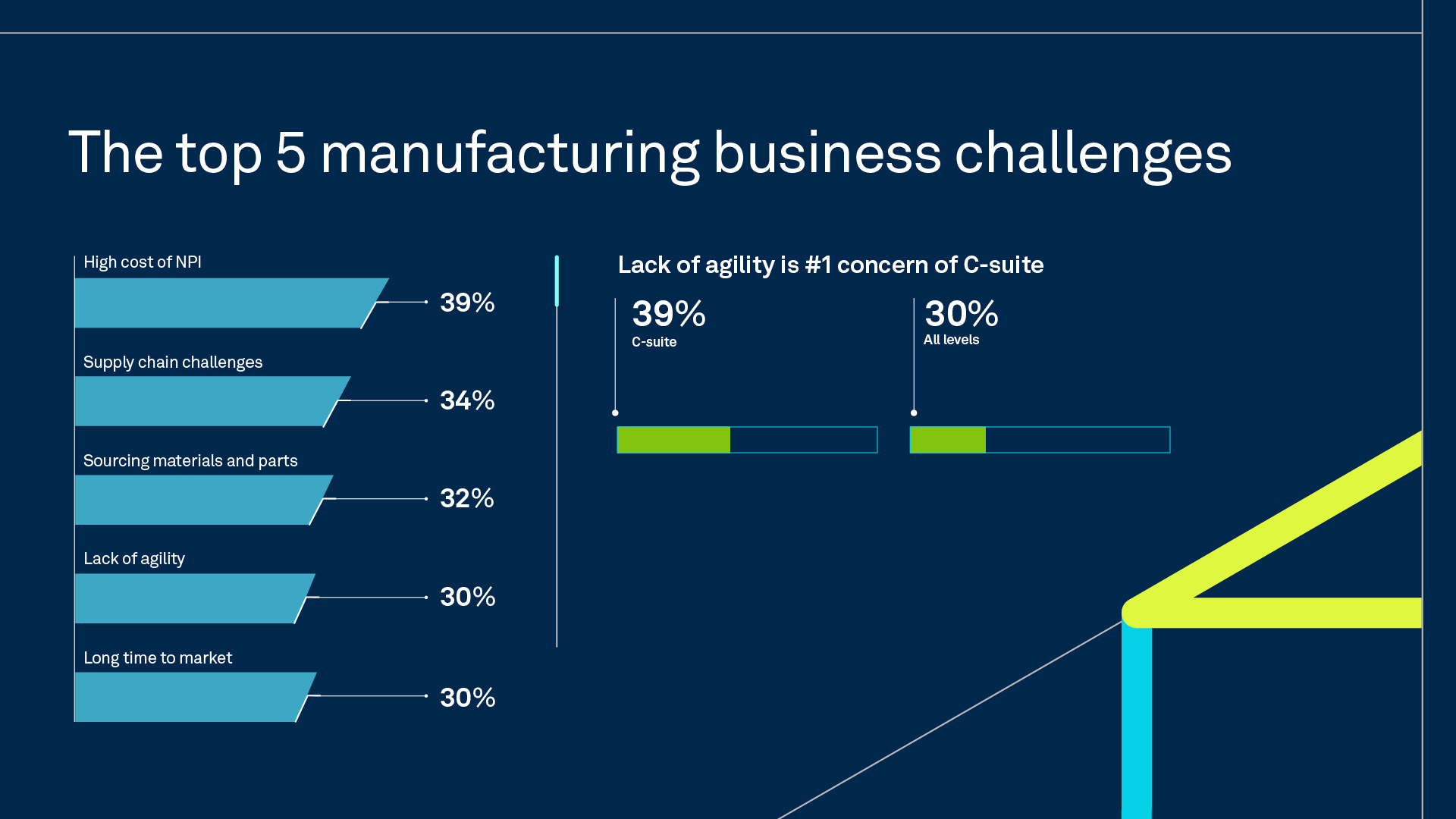

Manufacturing strategy and investment playbook

The latest market insights to inform your strategic direction with data from Hexagon’s Advanced Manufacturing Report 2025. Read more

From disruption to growth: Building an agile manufacturing business

With volatility defining today’s globalised environment, agility has emerged as the defining priority of manufacturing leaders. Insights from Hexagon’s 2025 Advanced Manufacturing Report reveal that 39% of C-level executives identify agility as their top strategic priority while each of the top five business challenges faced by the industry is intrinsically linked to agility.

How additive manufacturing and 3D scanning improves product quality

Additive manufacturing (AM), or 3D printing, is driving significant change in industrial production. By enabling complex, lightweight, and custom components, AM unlocks design possibilities previously impossible with traditional manufacturing. Yet, these benefits hinge on precise quality control, where 3D scanning becomes indispensable. Read more

Advanced Manufacturing Report

Develop an actionable strategy for agility. Connect your business goals with technology planning. Shift from survive to thrive. Read more [Picture source: Hexagon Manufacturing Intelligence on linkedin.com]

Why the automotive aftermarket is embracing 3D reverse engineering

When you think of a garage, you think calipers, micrometers, height gauges… But a laptop and a 3D scanner is probably not the first thing that comes to mind. Read more