Engineer’s Insight: How We Improved CNC Tolerances in One Year

In the competitive field of high-tech manufacturing, staying ahead means continuously refining processes and investing in the most advanced technology. Ductile CNC micromachining has improved the machining of technical ceramics and glass by achieving better surface finishes, higher dimensional accuracy, and reducing sub-surface damage. While traditional grinding and polishing remains essential for specific applications, CNC ductile…

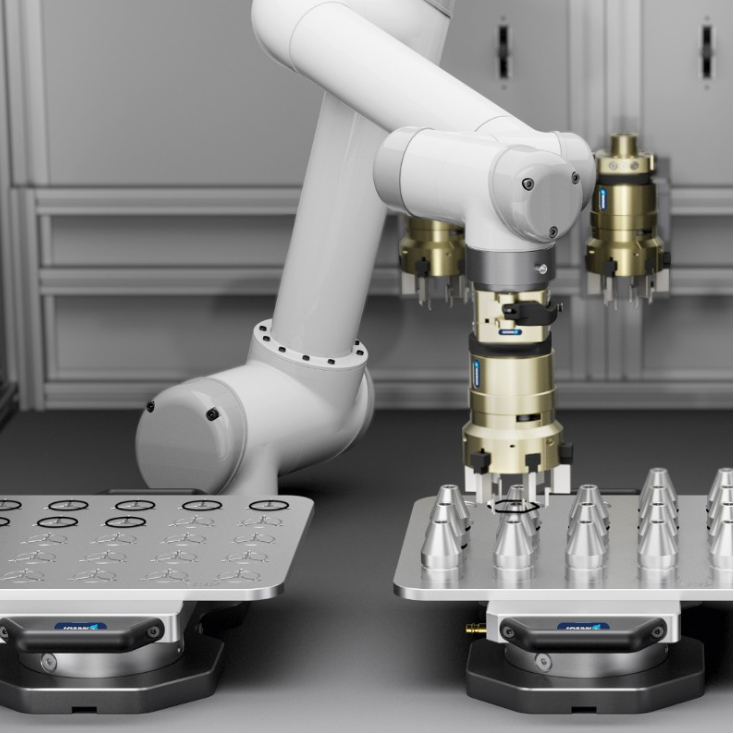

Precision in machining, purity in every detail

We manufacture complex components with micron-level tolerances, but production doesn’t stop at machining. At LouwersHanique, cleaning and contamination control are integrated from the start, with tailored strategies for each design. Read more and watch the video

Co-developing high-tech solutions in technical glass and ceramics

From concept development to re-engineering, LouwersHanique integrates seamlessly into your team to support every phase of the product lifecycle. Whether it’s thermal shaping, mechanical processing, hermetic bonding, or creating 3D microstructures, we offer engineering and material expertise that goes far beyond production alone. Read more [Picture source: LouwersHanique on linkedin.com]

What keeps your system from breaking down at 18kV in vacuum?

In critical applications like semiconductors, failure often starts where power passes through. That’s why engineers choose electrical feedthroughs based on Alumina ceramic insulators. Read more

Ultra-precise 3D freeform laser machining for medical applications

Selective Laser-induced Etching (SLE) stands as a cutting-edge production technology, for transparent brittle materials like glasses (ULE/Fused Silica/BF33) and crystals (Sapphire/YAG/Quartz). Through SLE, intricate 3D freeform structures become achievable, enabling the seamless integration of diverse functionalities such as mechanical (flexures), optical (micro lenses), and electrical functions within the 3D-optical microdevices. Read more

When is glass the right choice for your manifold?

If your application requires chemical resistance, dimensional stability, optical transparency, and absolute cleanliness, glass is the material of choice. Read more [Picture source: LouwersHanique on linkedin.com]

One Setup, Two Tasks: Precision Multitask Machining for Ceramic and Glass Components

In the world of precision engineering, efficiency, accuracy, and versatility are essential. While advanced machinery plays a crucial role in manufacturing, the expertise behind the process determines the final product’s quality. At LouwersHanique, we use advanced multitasking technology to integrate turning and milling operations, achieving high precision finishes. However, technology alone is not enough, our deep…

Why engineers should opt for SLE in optical bench production

At LouwersHanique, we use SLE (Selective Laser-Induced Etching) technology to create monolithic optical benches with integrated mechanical stops. This eliminates adhesives, simplifies assembly, and enables passive alignment for superior precision and efficiency. Additionally, the use of materials like fused silica and ULE ensure…

Advantages of quartz for high-tech manufacturing

Quartz and fused silica are renowned for their exceptional thermal stability, low thermal and electrical conductivity, optical transparency and high chemical purity. These materials also exhibit low coefficient of thermal expansion (0.55 to 0.57 x 10⁻⁶/°C) and can withstand temperatures exceeding 1,200°C without significant structural degradation. This makes quartz and fused silica the material of choice…

Students Test Nano-Volume HPLC Flow Cells Made by 3D Freeform Laser Shaping of Glass

For over a year, we have been collaborating on a cutting-edge research project focused on the integration of microfluidics into HPLC flow cells using laser glass processing. This research aims to enhance detection sensitivity and thereby improve the accuracy and precision of component measurement in pharmaceuticals. This project can not only contribute to the improvement of existing…