5 Key Differences Between Crossed Roller Linear Guides and Recirculating Ball Linear Guides

In this article, we will explore the utilization of bearings in mechanisms to ensure precise guidance and positioning in a single direction, be it linear or rotational. However, it is crucial to ensure adequate stiffness in all other directions to effectively guide the mechanism. The focus of this article is to examine the disparities between Linear…

Maximize your ROI with customised positioning stages from PM!

At PM, we understand that return on investment is crucial for your success. Our customers boost their throughput and reduce costs through our innovative solutions and extensive knowledge. Read more [Picture source: PM on linkedin.com]

High-precision positioning stages for the semiconductor industry!

We design, we manufacture, and we assemble it to meet your specifications. Read more [Picture source: PM on linkedin.com]

Taking custom positioning stages to the next level with precision!

At PM, we have an incredible team of engineers and machine operators who are experts in their field. Our designers have extensive experience in various applications, so you can trust that we know what we’re doing. What sets us apart is our vertical integration production model. Read more [Picture source: PM on…

Cross roller guides: overview, characteristics and applications

Crossed roller guides are designed for limited strokes and consist of two hardened rails with a crossed roller cage for bearing support in between. The use of rolling bearings allows for a low friction coefficient of <0.003. The rollers which are 90 degrees angled to each other, are held in place by a cage. These linear guides are suitable…

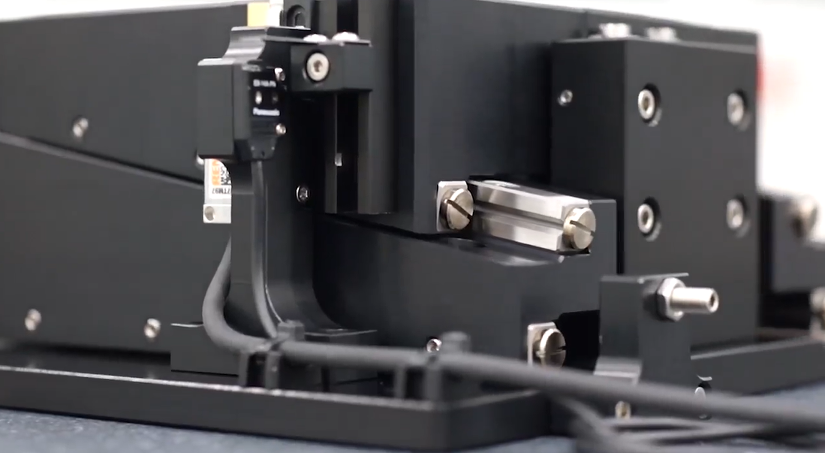

Piezo-driven Z-wedge stage with an open frame design

As specialists in the development and production of customised positioning stages, we have produced many designs. This video shows a piezo-driven Z-wedge stage with an open frame design. This stage can be used for inspection applications. [Source: PM on linkedin.com]

Customised Positioning Stages

PM is the brand for Customised Positioning Stages. With a rich history in developing stages for various industries, PM understands the requirements and can turn ideas into high-performance, high-quality products. Read more [Picture source: PM on linkedin.com]

Grinding is a crucial step in producing linear guides

Flat and cylindrical grinding are one of the core competencies of PM. These images were recently taken in one of the grinding shops. These rails are type O which will be combined with N-type rails and used with needle roller cages as shown in the last images. Read more [Picture source: PM…

Needle roller guides in both the vertical and horizontal axes of a gear hobbing machine

In the video, needle roller guides are being used in both the vertical and horizontal axes of a gear hobbing machine. This machine is used for manufacturing gears in industries that require exceptional precision, such as the watch industry is requesting.

Miniature linear slides for medtech | Robot-assisted surgery requires high precision in motion

This video shows the assembly of high-precision miniature slides for use in robotic surgery also called robot-assisted surgery. They require high precision, low friction, and smooth running.