Torque motors vs Conventional servo motors

Different motor types are used to provide rotary motion within industrial applications. Each application has different requirements for speed, torque and accuracy, as well as its constraints in build-in volume and budget. This page briefly introduces different types of motors and their performance in positioning/indexing applications. Please watch our webinar recording to find out more in-depth information.

Why use a vacuum-enclosed design?

A perfect vacuum is an environment without any matter of gas in it. In industrial applications, a vacuum environment is considered to have a pressure much lower than the atmospheric pressure and is therefore formally only a partial vacuum. In the semiconductor market, vacuum systems are used at various manufacturing stages to reduce impurities and prevent…

Boost your power, boost your game!

At Tecnotion, we specialize in pushing the boundaries of motor optimization, ensuring that your appliations not only meet but exceed expectations. We have the capability to customize iron core magnet plates by adding additional force to the existing motors, all without the need for any design modifications. This tailored approach delivers a substantial boost in motor force,…

Choosing the right motor just got easier!

Our simulation tool lets you input application data, instantly generates detailed reports and performance graphs, and even allows to save scenarios for future use, all with a single click. Say goodbye to manual calculations and hello to efficiency! Read more

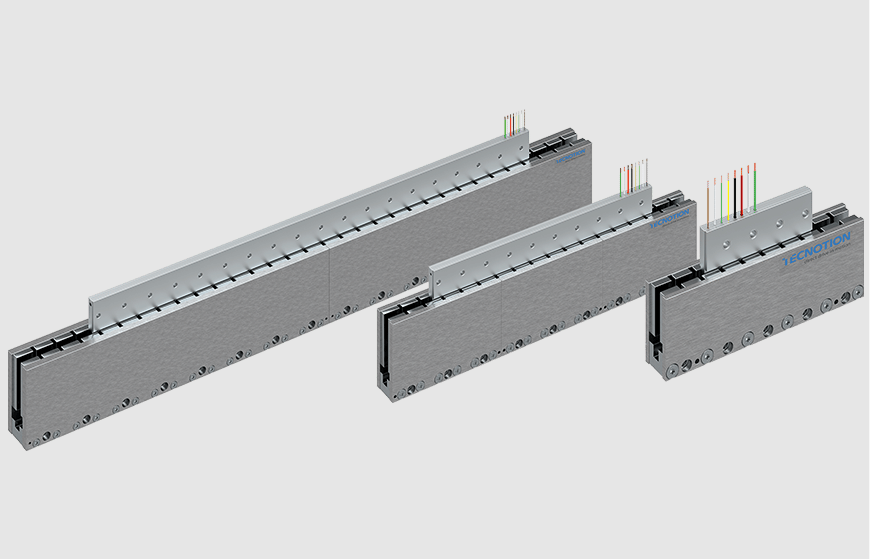

Linear motors vs other drive systems

Linear motion can be achieved by using different types of drive systems. Depending on the requirements of the application different drive systems can be beneficial for your machine. Belt drive, rack & pinion, ball screw and linear motors are often considered as four common linear drive systems. This page briefly introduces each of these systems,…

The new benchmark in vacuum motors

Generation 2 vacuum ironless linear motor series is designed with the unique challenges of vacuum applications in mind and based on years of collaboration with high-end semiconductor manufacturers. The portfolio is suitable for even the strictest vacuum requirements with a large force range. Read more

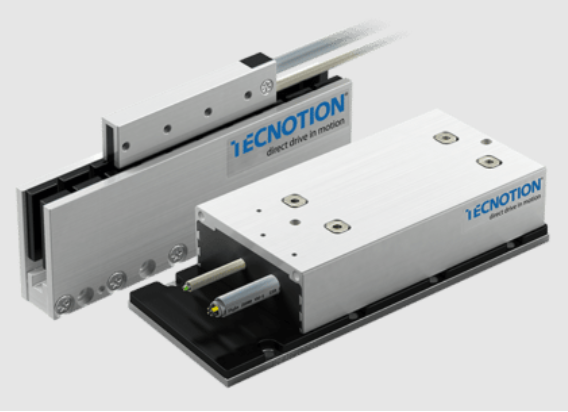

Linear, torque and custom solutions

Tecnotion direct drive motors are seamlessly integrated into a wide variety of applications, such as semiconductors, machine tooling, robotics, display applications and printing industry. As an independent supplier of linear- and torque motors we offer specialized motor technology to place in your motion solutions. We direct drive your motion technology. Read…

Delta Robot application

The new generation delta robots have one thing in common. Their design replaces the familiar servo motors with gearbox, opting for direct drive torque motors instead. Together with Tecnotion, Brom mechatronics designed and build the first delta robot production line to place flower bulbs into pots. The build-in frameless torque motors play an important role…

Tecnotion start implementatie Togetr Digital Factory

In de voorbije maanden is bij Tecnotion, gespecialiseerd in het produceren en customizen van hightech direct drive-motoren, de implementatie gestart van de Togetr Digital Factory-module. Directe aanleiding voor deze stap is de strategische visie binnen Tecnotion om operational excellence te bereiken, gecombineerd met de sterke quality first-ambitie binnen het Almelose bedrijf. Tecnotion zit in een groeiversnelling met een uitbreiding van zijn productiefaciliteiten en een…

Succes Tecnotion mede bepaald door roots Philips en ASML, ‘Inmiddels zijn we technologiemarktleider, op eigen kracht’

Binnenkort beslist Tecnotion, gespecialiseerd in het produceren en customizen van hightech direct drive motoren, over een nieuwe productielocatie in Oost-Europa. Hiermee wil het bedrijf invulling geven aan zijn strategie ‘lokaal verkopen, lokaal produceren’ en tevens klaar zijn voor de verwachte groei in toonaangevende markten. Het nieuwe hoofdkantoor in Nederland, dat in Q2 2024 in gebruik wordt genomen, levert hier ook een…